IP-3000 Visual Inspection Solution

The IP-3000 is a product developed to make a production line more reliable in-terms of visual inspection. Improving on common lapses on production lines such as:

- Visibility (Scope of Inspection)

- Accuracy (of Visual Inspection)

- Traceability

IP-3000 Development Concept

Visibility

Traceability

Visibility

Limitation of most visual inspection systems is the inspection only on one side of the target with limited motion/movement. With the IP-3000, 2 cameras are used to perform a top and side inspection. Also, 360 degree rotation movement is ensured with the IP-3000's special rotation mechanism.

Accuracy

Traceability

Visibility

Manual inspection accuracy heavily depends on operator's eyes. Being subjected to a microscope or magnifying lens to conduct a visual inspection is very taxing to the operator's eyes. The IP-3000 is designed to reduce the strain on the operator's eye therefore having a more reliable visual inspection station.

Traceability

Traceability

Traceability

It is often overlooked at is that most manufacturing defects are still detected at a manual visual inspection station. The IP-3000 is used to record and manage defective images to achieve true traceability.

IP-3000 Key Features

IP-3000 Magnification

Showcase the IP-3000's Capability of magnified viewing of the target location.

IP-3000 3D Viewing

One of the greater advantages of the IP-3000 over other visual inspection solutions is its 3D viewing capability.

IP-3000 Brightness Adjustment

Target location is a narrow dark spot? Not a problem with the IP-3000 and its capability to brighten up the target location.

IP-3000 Swivel Function

A shortcut function for a quick side to side inspection of a certain location.

Sample Images from IP-3000

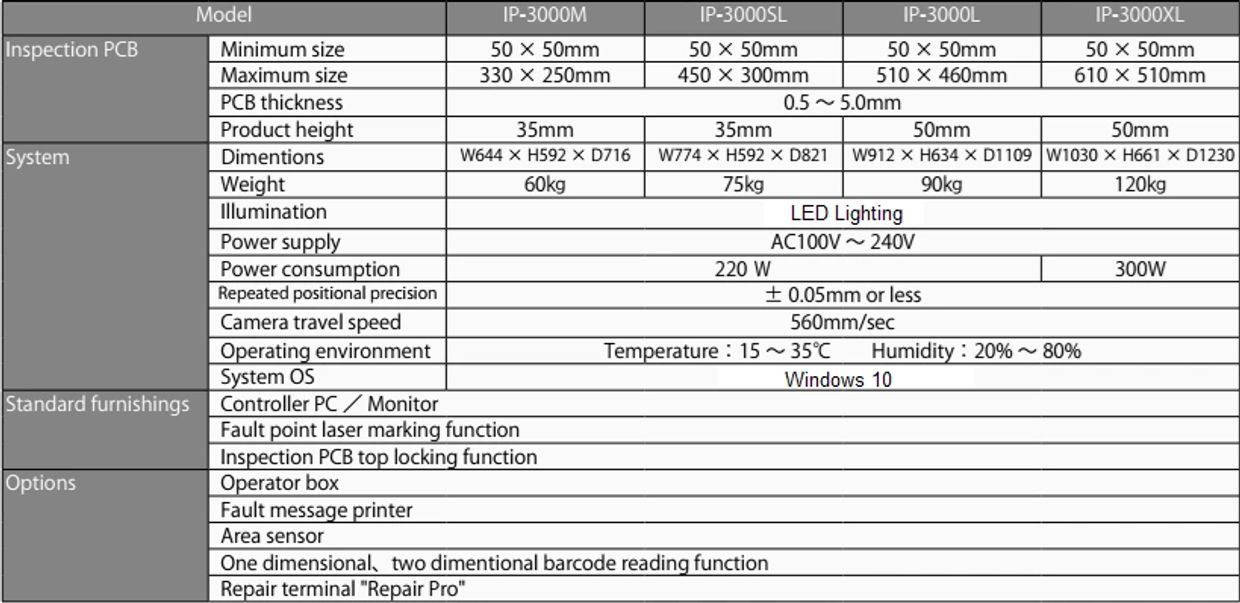

IP-3000 Specification

IP-3000 comes in different sizes to accommodate variety of different sizes of target devices.

IP-3000 Inline System

For Inline system integration

IP-3000 Table Top System

Space Saving Solution

WIT JAPAN CORPORATION

Copyright © 2025 WIT-JAPAN CORPORATION - All Rights Reserved.